Concealed Fastener Panels

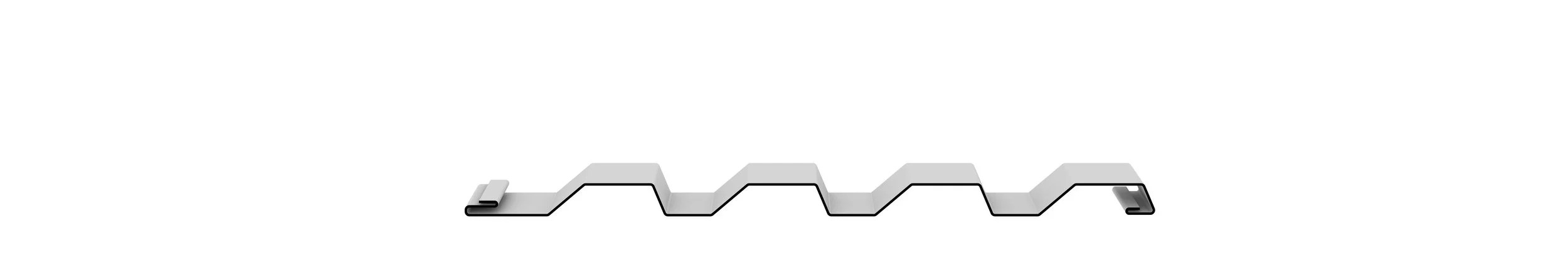

Wave Panels

When specifications call for a textured wall design without visible fasteners, the Wave Panels offer an excellent solution.

Wave Floating is installed horizontally utilizing hidden clips and fasteners for panel lengths greater than 40', resulting in a monolithic and aesthetically pleasing appearance.

Wave Fixed, also installed horizontally, is installed with an integral fastening flange that is rollformed into the panel during the manufacturing process and can be utilized for panel lengths 40' or less. Wave Fixed requires a specific clip that is used as a starter panel that attaches to the base trim.

Specifications & Details

-

Concealed fastener wall panel

For use with Fablok fasteners or angle clips

Also referred to as

"Shadow Rib" panel

Manufacturing Facilities

Sunnyvale, TX - Extended lead time required.

Note

Oil Canning is a natural occurrence in metal panels and is not a cause for panel rejection.

-

Air Infiltration

ASTM E283

Water Penetration

ASTM E331

Acoustical performance

ASTM E90

Testing Data

-

Panel width

16"

Panel height

3"

Coating

Kynar 500® (PVDF)

Substrate

- Standard 24 GA Galvalume®

- Optional 22 GA Galvalume

FW Panels

FW Panel is a 1 1/2-inch deep flush metal panel designed for use in vertical and horizontal applications.

Available 12-inch panel width options include: vee grooves, inverted plank, reveals of up to 3 inches, or a traditional smooth appearance. Regardless of the pattern, the 1 1/2-inch depth and the tongue-and-groove engagement remain the same.

Specifications & Details

-

Maximum Length:

24 GA 2' minimum and 8' maximum

22 GA 2' minimum and 15' maximum

Manufacturing Facilities:

Adelanto, CA; Houston, TX

Note:

Oil canning is a natural occurrence in metal panels and is not a cause for panel rejection.

-

Uplift Test:

ASTM E1592 (FW Panel)

Note:

No testing data on FW Reveal

Testing Data:

For available Test Data, Section Properties or Load Tables, please visit our downloads section.

-

Panel widths:

12"

Pan configurations:

Inverted Plank, Flat, Vee Grooves

Reveal Options:

1" to 3" (panel remains at 12" and reveal size increases coverage)

Coating:

Kynar 500® (PVDF)

Substrate:

- Standard 24 GA Galvalume®

- Optional 22 GA Galvalume

MSR Panels

Combining aesthetics and strength in one panel, McElroy Metal offers MSR, a concealed fastener wall panel. MSR's bold profile adds curb appeal to most any project while providing engineering and weathertightness characteristics demanded by architects and owners.

Specifications & Details

-

Concealed fastener wall panel:

For use with Fablok fasteners or angle clips

Also referred to as:

"Shadow Rib" panel

Manufacturing Facilities:

Sunnyvale, TX - Extended lead time required.

Note:

Oil Canning is a natural occurrence in metal panels and is not a cause for panel rejection.

-

Air Infiltration

ASTM E283

Water Penetration

ASTM E331

Acoustical performance

ASTM E90

-

Panel width:

16"

Panel height:

3"

Coating:

Kynar 500® (PVDF)

Substrate:

- Standard 24 GA Galvalume®

- Optional 22 GA Galvalume

Nostalgia Board & Batten

Our Nostalgia Board & Batten concealed fastener siding system offers the time-honored look of wood siding without the hassle of ongoing maintenance.

From residential to light commercial, building owners and designers appreciate the unique aesthetic appearance, carefree maintenance, and increased resistance to fire, rot, and insects over its wooden predecessors.

The standard paint system for our Nostalgia Board & Batten panel is Kynar 500® (PVDF), the industry's best coating for long-term protection against panel chalk and fade.

Specifications & Details

-

Manufacturing Facilities:

Produced in Houston, TX

Installation:

Must be installed over a solid deck

Note:

Oil Canning is a natural occurrence in metal panels and is not a cause for panel rejection

-

ASM E283 (Air) & ASTM (Water)

Pending

ASTM E1592 Uplift Tests

Pending

-

Panel Width:

12"

Coating:

Kynar 500® (PVDF)

Substrate:

Standard 24 Ga Galvalume®

Visionline F-Series Wall System

Visionline F-Series Wall system is ideal as a facade or rain screen and adds architectural styling and beauty to any project at a price point much lower than ACM systems. F-Series is a solid metal, flat plate wall panel system that does not require field-applied sealants, extrusions, gaskets, or exposed fasteners, which reduces onsite labor expense. Common applications include walls, facades, and rain screen, in both large sections and for architectural accents.

Available in McElroy’s architectural colors, F-Series panels are an excellent complimentary product to McElroy’s other roofing and siding systems. Architects and designers can mix and match components to achieve the desired architectural look.

F-Series panels are manufactured from a 22 gauge Galvalume steel substrate and coated with Sherwin Williams Fluropon PVDF (Kynar 500®) coating. Standard sizes are 16" x 24", 16" x 34" and 16" x 54" in 1" depth. Other sizes are available - please inquire for details.

Specifications & Details

-

- 22 Gauge Galvalume Substrate

- Fluropon PDVF (Kynar 500) coatings

- Field applied sealants, exposed fasteners, gaskets or extrusions are not required

-

- Air Infiltration in accordance with ASTM E 283 a 1.57 PSF

- Water Penetration in accordance with ASTM E 331 at 6.24 PSF

- Pressure Equalized Rain Screen Performance in accordance with AAMA 508

-

Standard Sizes. Please inquire regarding other sizes.

- 16" x 24"

- 16" x 34"

- 16" x 54"

Met-Tile Metal Tile Panels

Met-Tile is lightweight, energy efficient and aesthetically attractive. A Met-Tile roof looks so much like tile, most people are surprised to learn that they are actually metal roof tiles.

Specifications & Details

-

Minimum slope (with sealant):

1 1/2:12

Minimum slope (without sealant):

3:12

Installation:

Must be over solid deck

Manufacturing Facilities:

Sunnyvale, TX

Note:

Oil Canning is a natural occurrence in metal panels and is not a cause for panel rejection

-

Fire Rating:

Class A

Florida Approval:

17905.1

-

Panel lengths:

2' - 20' (in 1' increments)

Steps:

1' on center

Panel width:

38 5/16"

Panel coverage:

36 3/16"

Coating:

Low gloss, Kynar 500® (PVDF)

Substrate:

26 GA Galvalume® stucco embossed only

Milan Steel Shingles

Milan steel shingles add beauty and curb appeal to any home or business. Milan provides the aesthetic appearance of shingles, slate or shake with all the benefits of metal. Offering eight attractive Kynar 500®(PVDF) colors as well as Slate and Shake Kynar 500 Prints, McElroy Metal’s Milan Steel Shingles will complement any exterior design palette.

Specifications & Details

-

Minimum slope:

3:12

Panel exposure:

39" x 12"

Panels per square:

30.77

Note:

Four-way interlock system secured to the roof using aluminum fastening clips

Installation:

Can be over most existing asphalt shingles or solid deck

-

Fire Rating:

UL 790 Class A or Class B (depends upon exact roof preparation)

Uplift Test:

UL 1897

Texas Department of Insurance:

RC-463

Florida State Approval:

#19173.1

-

Coating:

Low gloss, Kynar 500®/Hylar 5000® (PVDF)

Designer prints in Low gloss Kynar 500®/Hylar 5000® (PVDF) are also available

Substrate:

29 GA G90 Galvanized